Historic find in The Perth Mint's coin press room

During engineering works in The Perth Mint's coining press room, workers cut through a concrete floor and revealed a brick-lined pit containing two large gears fabricated in 1896. Curator Natasha Fenner explains more about the extraordinary find and what it means for our heritage collection.

Can you tell us about the significance of the recent historical discovery made at The Perth Mint?

The Perth Mint is a permanent listing on the Western Australian State Heritage Register. The grand design of the main administration building reflects the importance of gold to Western Australia’s economy.

Behind our striking historic building sits an industrial factory where workers refined gold for 91 years and still make coins today. The factory has undergone many changes over the past 125 years as technology has developed. Recent engineering works in our coining press room uncovered the impressive driving gears from the original rolling mills. Their discovery is significant as little remains of the steam powered setup that originally drove coining operations.

What was the initial reaction of the Heritage Council of Western Australia upon learning about the discovery of the large gears?

The Mint notified the Heritage Council as soon as the historic find occurred. Heritage Council officers agreed the gears were rare surviving evidence of the late nineteenth century industrial technology used at the Mint. The site was recorded in detail which included taking measurements, photographs, and a 3D scan. The two gears, mounting plates and fixtures, were then carefully removed by experienced contractors.

Can you share some insights on the research process you undertook to interpret the findings?

Early plans and photographs confirmed that the location of the pit matched to the original rolling mill machinery. Old sales catalogues of Birmingham machinery manufacturer, Taylor and Challen, explained the mechanics of nineteenth century rolling mills. A series of gears transferred power from a large steam engine to the rolling mills. The gears were connected by metal shafting that ran in a series of pits underneath the mills.

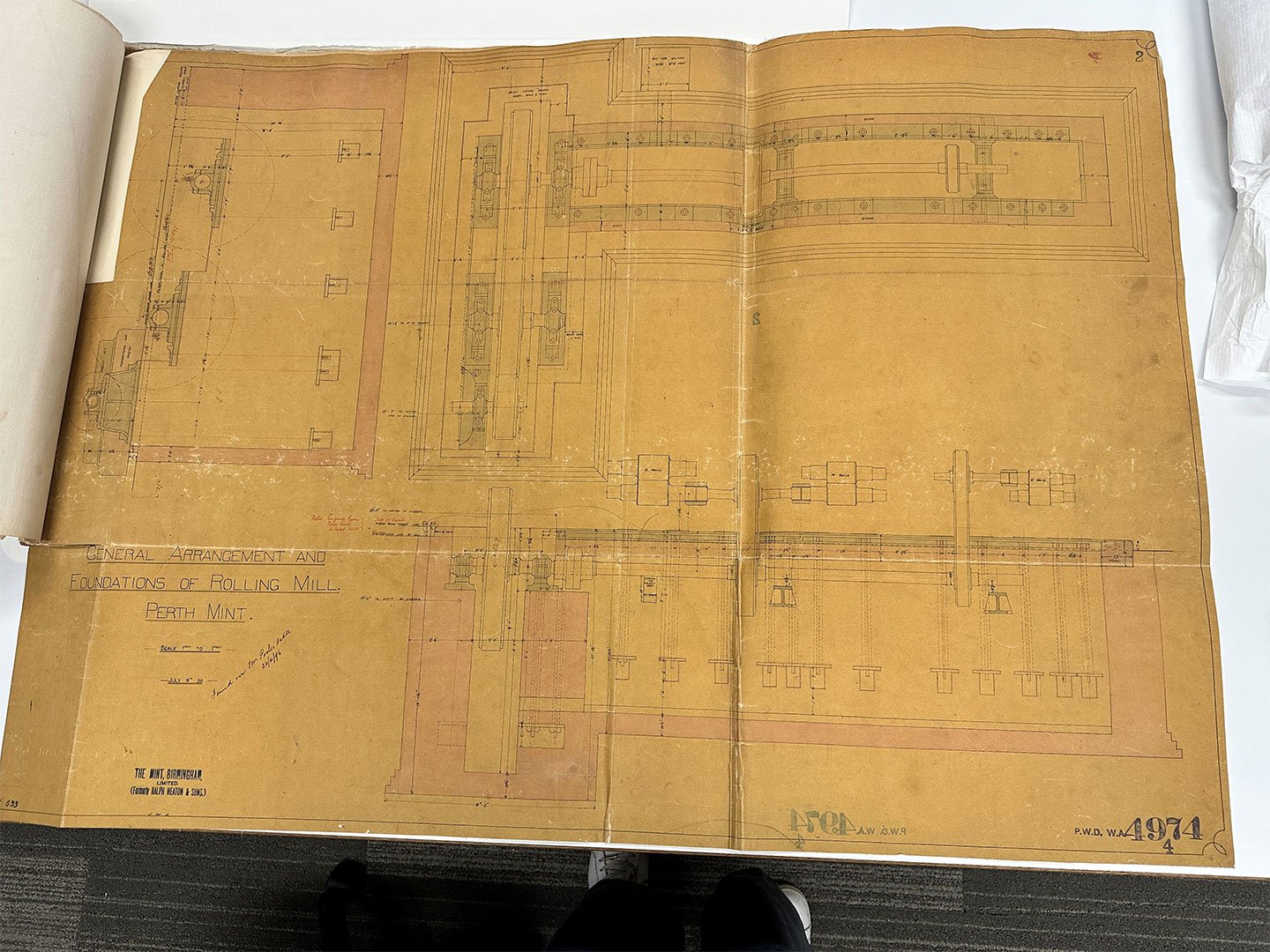

The Perth Mint records showed that another Birmingham manufacturer, The Mint, Birmingham, won the contract to supply the original machinery. The State Government’s Treasury Department approved the order on 19 January 1896. Parts were ready for shipping to Perth in February the following year.

The exact arrangement of the gears was confirmed when the 1896 plan for the General Arrangement and Foundations of Rolling Mill, Perth Mint was found in archives held at the State Records Office.

State Records Office of WA Cons 1647 04974

State Records Office of WA Cons 1647 04974

Could you elaborate on the role of the uncovered gears in the original operations of The Perth Mint?

The Mint’s coining machinery was originally powered by a large steam engine positioned in the centre of the Coining Room. This was connected to a huge boiler in the room next door. Power was transferred to the rolling mills by a series of driving gears. The driving gear arrangement had one small and two much larger gears. The small and one of the large gears were recovered. The second large gear remains buried as it was outside the area disturbed during engineering works.

Large gears, which have a long radius, rotate at a slower speed than small gears. With a fixed power source, reducing the speed of rotation is important to increase torque forces. Metal rolling needs large forces to squeeze a bar of solid gold between a pair of metal rollers. A thin, even strip of gold is produced that coin blanks are cut from.

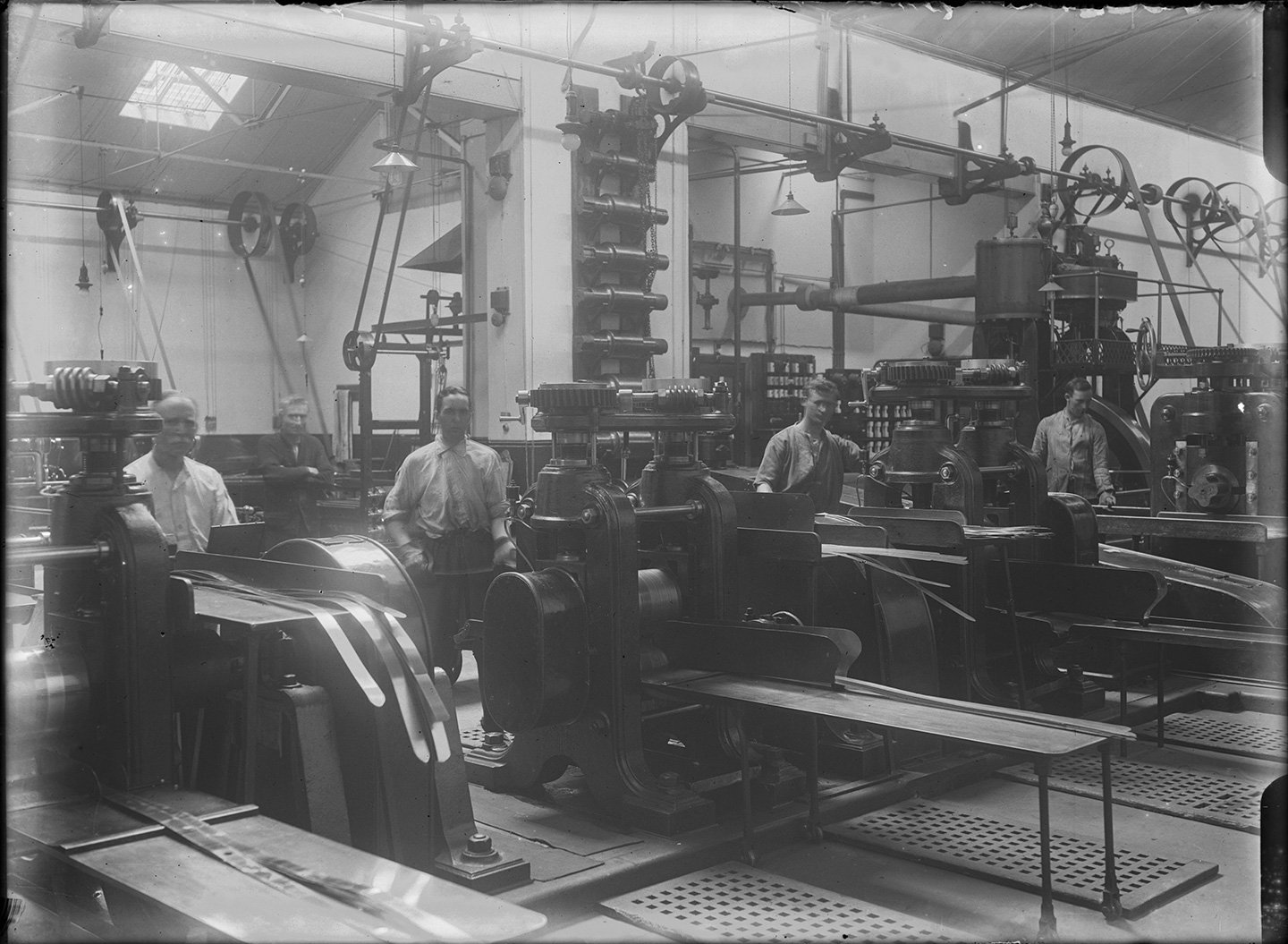

The original rolling mill and Perth Mint employees, 1919 - From the archives of the State Library of Western Australia <SLWA_b2990171_8>

The original rolling mill and Perth Mint employees, 1919 - From the archives of the State Library of Western Australia <SLWA_b2990171_8>

What does the discovery mean for The Perth Mint heritage collection?

The gears are an exciting addition to The Perth Mint heritage collection as few parts of original machinery still exist. Most have been replaced with newer technology, changing the layout of machinery on the factory floor. The gears will be conserved, and plans made for their display to explain how the Mint’s machinery was powered during its early years.