How does a gold refinery work?

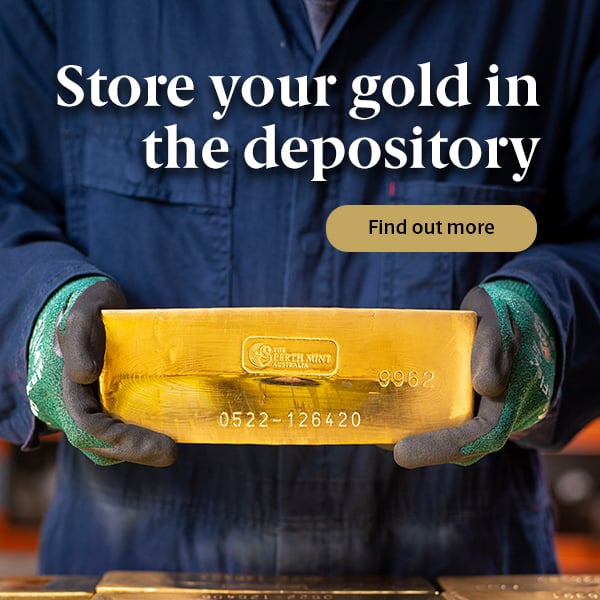

When looking to partner with a refinery, you’re looking for competitive and sustainable rates, fast payments, and technical superiority that exceeds industry expectations.

But how exactly does a refinery work? We explain the refining process and what makes quality bullion and coins:

The gold refining process

Ensuring precious metals are refined by a reputable and accredited refinery can make all the difference for the producer and their business goals.

The basic overview is that a refinery receives raw material such as gold nuggets or doré from mining companies. This material is then heated to molten metal and chlorine gas injected to separate the gold from other metals impurities. Once separation has occurred, the gold is tested, also known as assaying, to determine the purity before it’s cast into bars.

A more detailed step-by-step process guide explains what we do here, specifically, at The Perth Mint Refinery in Australia to ensure our partners receive the highest-quality and purity of gold.

1. Doré melting

The assay process starts here. The Melt House is where rough gold deposits are melted and electromagnetically stirred. Immersion dip sampling also takes place to extract representative samples from the mixed metal prior to the analysis stage.

2. Sampling

Five samples are then taken, with three sent to the laboratory and the other two retained for independent customer and umpire analysis.

3. Assaying

In one of the most advanced and best equipped precious metals assay laboratories in the whole of the southern hemisphere, you’ll find our highly trained team of chemists and technicians with more than 200 years’ combined experience in precious metals analysis between them.

Our bullion analysis relies on high accuracy micro balances. These balances record the weight to one-millionth of a gram, with the newest balance reading ten-millionth of a gram. The whole process is highly technical, skilled, and accurate.

In this part of the process there are two further steps:

- XRF screening takes place to determine the gold, silver and base metals.

- Once complete, fire assay is used to separate the base metals from the precious metals. This dual stream analysis is conducted by two separate analysts to ensure the final results provide the greatest accuracy possible and confirm we have obtained a truly representative sample of the melt.

Our assaying is so accurate that our gold analysis has been tested to be within 0.001 per cent for gold by the London Bullion Market Association (LBMA) – the global gold industry’s premier regulatory body.

It’s this level of accuracy, and uncompromising attention to detail, that producers need most. Ultimately, it’s this that gives you your greatest return.

4. Payment

Once the assay process is complete, it’s time for payment and the next steps for your product in the market. This is where our Treasury team come in. Our experienced traders and logistics specialists have long-standing relationships with leading industry professionals and have a track record of working with our producer partners to help maximise returns with minimal risk.

A world leader in precious metals

The Perth Mint Refinery operates across the entire precious metals value chain, from refining right through to the delivery of physical products and investment solutions to markets in more than 130 countries worldwide, including Europe, North America and Asia.

Our refining business has been built on long-term relationships with Australia’s largest mining companies. Our overriding commitment is to provide our partners with reliable and efficient results, supported by a secure, global, and government-backed refinery.