Finishing touches make all the difference

The Perth Mint applies different finishes to precious metal coins. A ‘finish’ is a surface treatment that enhances the appearance of the coin’s design.

Techniques that achieve the desired effect require expert skills and specialist equipment. Here is our quick guide to various finishes that appear regularly on our collector, or numismatic, releases.

By way of introduction, look at the uniform finish of any coin in your loose change. The designs and inscriptions stand slightly proud of the surrounding area. The natural shadowing and reflections of this ‘raised relief’ makes the design visible. On circulating coinage, it is not worth contrasting these elements any further from the flat coin ‘table’.

In precious metals minting, however, we go to great lengths to define and enhance designs with different finishes as a measure of the coin’s superior quality and desirability.

Proof coins

A coin with a proof finish is the Rolls Royce of minting. This type of coin is generally recognised by its delicately frosted (matt) raised design elements, which are thrown into prominence by a shiny, mirror-like table.

Production of proof quality coins is an involved process requiring specially prepared blanks that are buffed to a highly-polished state. Manufacture of proof dies is extremely intricate.

A die is a hardened metal stamp featuring a reversed impression of the coin design. In creating a proof die, the impression is covered with transparent tape. Using a surgical knife, the tape covering what will be the raised design elements is gradually removed with a steady, skilled hand. The exposed design is then sandblasted to create a frosted effect that will be replicated during the coin strike.

The remainder of the tape is removed and the table area of the die is polished with ‘lapping’ sticks and diamond paste.

Proof blanks are struck at least three times in succession with these remarkable dies to ensure the design appears crisp and clear on the flawless table of the finished coin.

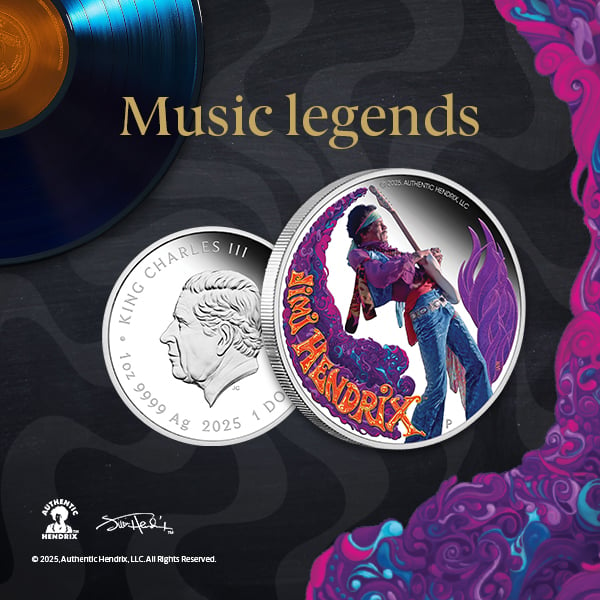

Coloured coins

There is a long history of coloured numismatic pieces. They became especially popular during Queen Victoria’s Golden Jubilee in 1887, which prompted a huge demand for Royal memorabilia. Nineteenth century techniques saw enamel applied in layers, fired, and then ground down to create various shades.

In the spirit of this tradition, The Perth Mint has coloured certain coins since 1996. The process employed has evolved over the years. Today we use advanced LED UV printers for exceptional results.

Parts of the coin design to be coloured are mapped with a digital camera. The precise parameters are transferred to the printer which applies a white primer and then coloured layers to the design. Coins undergoing this treatment are then cured overnight to ensure the eye-catching colours remain stable over time.

With nearly three decades experience, The Perth Mint has developed an unrivalled reputation for its expertise in producing coloured coins.

Gilded coins

Like colour, gilding applies a decorative layer on selected areas of a coin. In most cases, we electroplate a thin layer of 24-carat gold onto a silver coin.

Electroplating works by electrolysis, which uses electricity to drive a chemical reaction.

The coin is dipped in gold based electrolyte solution. During the process, particles from a positively charged gold ‘anode’ are deposited on the negatively charged silver ‘cathode’ (the exposed silver). The duration of the electric current determines how many microns of gold are applied to the coin.

The Perth Mint has issued gilded coins since the 1990s. Today, Gilded Kookaburra, Lunar, and Koala coins, on which the animal is enhanced with a precision applied coat of fine gold, are among some of our most popular annual releases.

Antiqued coins

Antiquing was exclusively developed by The Perth Mint to give silver coins a unique look conveying the surface characteristics of an ancient artefact. It works particularly well when applied to coins celebrating themes from history and antiquity.

Struck pieces ready to be antiqued are immersed in warm oxidising solution to blacken the silver. Later in the process, the coin design is gently abraded to partially remove the dark patina from raised areas, leaving the deeper parts of the design black.

Finally, the coins are lacquered, protecting the surfaces from further change, and even allowing them to be handled safely with ungloved fingers.

Antiquing has had an enormous impact on creativity in modern numismatics. Proof, coloured, and gilded coins require a protective acrylic capsule to remain in pristine condition. To prevent such coins chaffing on the capsule, the rim must be the thickest part of the coin.

Antiqued coins are freed from these restraints, enabling our designers to explore collector themes in original and innovative ways, including three-dimensional inserts. Examples include the extraordinary Golden Treasures of Ancient Egypt 2oz Silver Antiqued Coin, the equally remarkable Tears of the Moon 2oz Silver Antiqued Coin, and the ever-popular Rotating Lunar Charm 1oz Silver Coin Series.

An art in itself

There are many steps in the production of precious metal coins, including refining, blanking, image design, die making, striking, inspection, and packaging. Applying beautiful finishes is an art in itself – one that has been proved to have a significant effect on the way our superb releases resonate with collectors.